In the high-risk arena of working at heights, the safety harness is undoubtedly the key 'protagonist' in protecting workers' lives. However, a heartbreaking accident serves as a stark reminder that even with the 'presence' of a safety harness, tragedy can still strike if its quality and retirement standards are neglected.

The Accident Serves as a Wake-Up Call.

On April 8, 2021, a fatal accident occurred at a power generation company during high-altitude operations. While moving along a structural pole, a worker lost his footing and fell. Although he was wearing a safety harness, the harness failed to prevent the fall as it broke at the back connection point, ultimately resulting in his tragic death.

This accident not only brought immeasurable grief to the victim's family but also served as a stark reminder of the importance of workplace safety.

The accident investigation report identified several indirect causes. The primary contractor failed to fulfill its responsibility for workplace safety, unlawfully subcontracting the project to a secondary contractor. Additionally, the procurement, inspection, storage, and distribution of personal protective equipment (PPE) were poorly managed, with inspection processes being merely procedural. On-site management was ineffective, failing to identify the defective safety harness in time, reflecting a severe lapse in safety oversight.

A series of negligence and mismanagement ultimately led to this tragic incident, underscoring the critical need for stringent safety measures and enforcement.

As the 'lifeline' for workers at heights, the quality and safety of safety harnesses are of paramount importance. However, over time and with changing environmental conditions, safety harnesses may gradually wear out, deteriorate, or even fail. To ensure the safety of every high-altitude worker, it is crucial to strictly adhere to the retirement standards for safety harnesses.

1. Service Life of Safety Harnesses

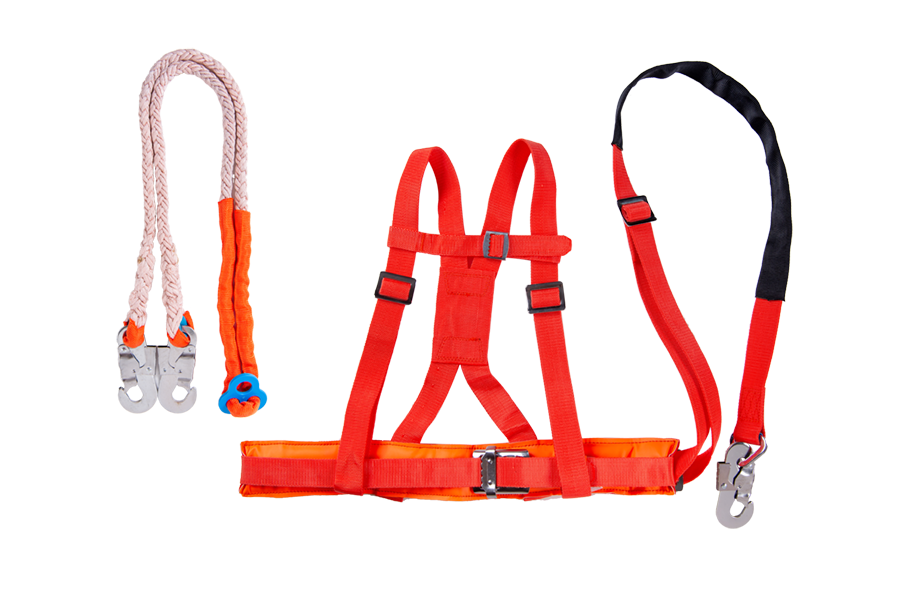

(1) Pole Work Safety Harness

The service life of a pole work safety harness should generally not exceed three years, and it must be inspected by a professional institution annually. Within two years from the date of purchase, two harnesses from the same batch must be randomly selected for dynamic and static mechanical performance tests in accordance with GB6095 standards. If the harnesses fail the tests, the entire batch must be discontinued. Thereafter, batch sampling tests must be conducted annually.

(2) Work Positioning Safety Harness

The service life of a work positioning safety harness should generally not exceed five years. Within two years from the date of purchase, two harnesses from the same batch must be randomly selected for static mechanical performance tests as per GB6095 standards. If the harnesses fail, the entire batch must be discontinued. Subsequent annual batch sampling tests are required.

(3) Fall Arrest Safety Harness

The service life of a fall arrest safety harness should generally not exceed five years. If a fall incident occurs, the harness must be inspected by a qualified professional. If any damage affecting its performance is found, it must be replaced immediately.

Within two years from the date of purchase, two harnesses from the same batch must be randomly selected for dynamic and static mechanical performance tests following GB6095 standards. If the harnesses fail, the entire batch must be discontinued. Subsequent annual batch sampling tests are required.

For fall protection equipment exceeding its service life, if continued use is necessary, semi-annual sampling inspections must be conducted, and only those that pass can remain in use. In environments with extreme conditions or high-frequency use, the service life should be further reduced accordingly.